- Code:

- JV200-160

|

Availability: |

|

Description

Description

Mimaki JV200-160 | 64" Eco-Solvent Printer

The Mimaki JV200-160 is a next-generation 1.6m wide format solvent printer designed to deliver exceptional output with ease, efficiency and versatility. Engineered for signmakers, vehicle wrappers and print providers seeking an affordable, high-performance print-only solution, the JV200-160 builds on Mimaki’s trusted heritage with a new print engine derived from the flagship 330 Series.

High-quality wide format printing – redefined for today’s sign and display professionals

Combining vibrant, long-lasting output with intuitive operation and enhanced workflow features, the JV200 is ideal for a wide range of indoor and outdoor applications. Whether you’re expanding production or upgrading from an older model, it offers an impressive balance of speed, quality and reliability.

Ideal for producing high-impact signage, display graphics, vehicle liveries and promotional prints, the JV200 supports a variety of media including self-adhesive vinyl, banners, canvas and backlit films. The advanced printhead configuration and precision drop control ensure smooth gradations, vibrant colour, and crisp detail – even at high speed.

With intuitive controls, improved media handling and user-focused features throughout, the JV200 is as easy to operate as it is to integrate into your existing setup. Whether you’re printing short runs or high-volume jobs, this solvent printer provides the productivity and quality to help grow your business and explore new opportunities

Product Outlines

-

- Beautiful printing. Mimaki's flag-ship printer's "330 Engine" a single print head is mounted to achieve high image quality.

- Reliable even during busy periods. Highest practical print speed at entry level: 17.0 m²/h

- Simple design that is easy for anyone to use. Easy to work with, easy to check, and easy to maintain.

- New SS22 ink, which does not contain GBL, a controlled substance, is provided in an environmentally friendly paper cartridge.

|

Suitable for cost effective production of large,

|

|

Effortless Control and Operations

|

|

|

|

|

Powered by the Mimaki 330 Print EngineTechnology you can trust.

Inherited from Mimaki’s award-winning 330 Series, the advanced print engine at the heart of the JV200 delivers class-leading output quality and performance. Featuring high-precision dot placement, variable drop printing and intelligent waveform control, it ensures accurate, vibrant prints across a wide range of substrates. The printhead configuration enables fast throughput without compromising detail, helping you meet tight deadlines while exceeding client expectations. |

|

High productivity and new revenue opportunitiesWith fast print speeds, reliable unattended operation, and with a choice of Mimaki’s three popular eco-solvent inks, the JV200 is built for productivity. It’s equally suited to high-volume workflows and bespoke projects, giving sign and graphics providers the flexibility to handle diverse client demands.

|

|

|

|

|

Mimaki BS4 and SS22 inksMaximum flexibility to suit every business

New Sustainable Solvent Ink New Budjet Solvent Ink

|

|

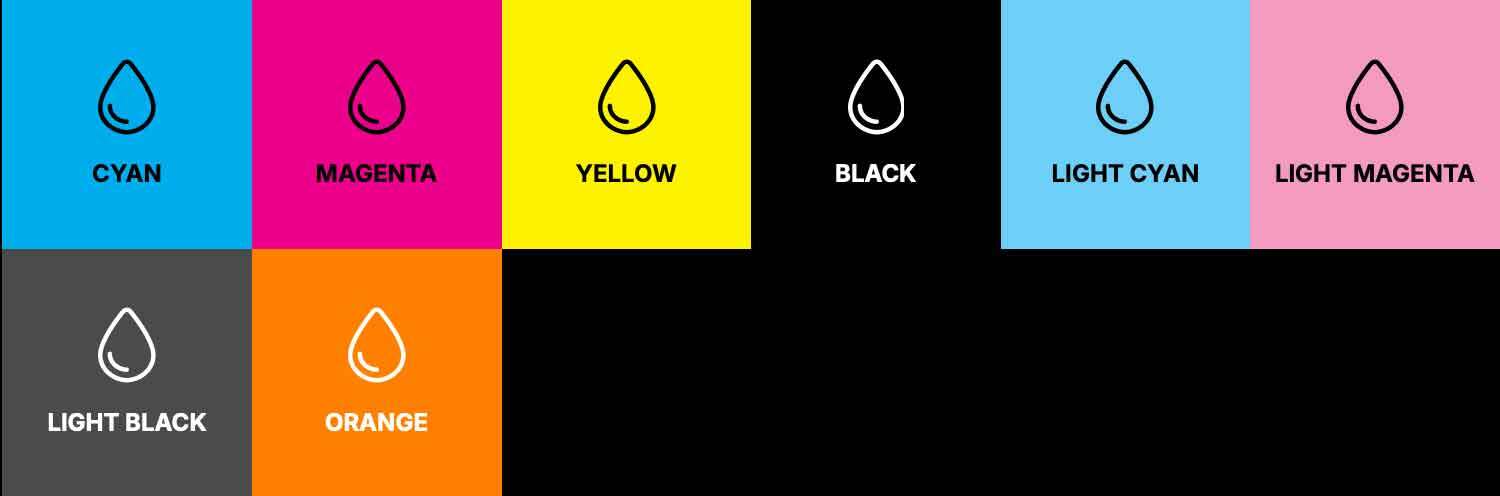

Available ColoursMimaki's inks deliver highly consistent results, with special colours and effects adding to the creative capabilities of your printer. NB: Not all colours are available in all inksets shown. Please consult with your supplier to confirm.

|

|

|

|

|

Powerful, Integrated RIP & Cutting PackageIntegrate your workflow with Mimaki's easy to use software

Mimaki RasterLink 7 RIP software enables the advanced features of Mimaki’s range of printer and printer/cutters, to assure the highest print quality with serious ease of use. Delivering smooth tonal gradation, accurate production of special effects, swift PDF processing and much more. Mimaki FineCut works alongside RasterLink to seamlessly integrate the design > print > cut process as part of an intuitive workflow. With powerful features such as Mimaki’s unique die cutting process and the newly added ID Cut barcoding function. |

Watch this Video

Specification

| Product |

JV200-160 |

|

|

Print Head |

On-demand piezo heac |

|

|

Print Resolution |

600dpi, 900dpi, 1200dpi |

|

|

Print Gap |

By manual 2 levels (1.5/2.0 mm) |

|

|

Ink / Type and Colour |

Eco-solvent ink |

|

|

Ink / Capacity *2 |

SS22:440ml Ink cartridge / 1L Ink pack |

|

|

Media |

|

|

|

Maximum print width |

1,610mm (63.4") |

|

|

Maximum width |

1,620mm (63.8") |

|

|

Thickness |

1.0 mm or lower |

|

|

Roll diameter |

φ180 mm or less |

|

|

Roll weight |

25 kg (55.1 lb) or less |

|

|

Roll inside diameter |

2 inch / 3 inch |

|

|

Other |

|

|

|

Interface |

Ethernet 1000 BASE-T (Recommended) / USB2.0 Hi-speed |

|

|

Certifications |

VCCI class A, FCC class A, ETL IEC 62368-1, |

|

|

Power supply |

Single-phase (AC 100–120V/200–240V)×2 50/60Hz±1Hz |

|

| Power consumption |

Max. 1,320 W x 2 or less / Min. 4.5 W or less (Sleep mode) |

|

| Operational environment |

Temperature: 20–30 °C (68–86 °F) |

|

| Dimensions (W×D×H) |

2,770mm × 748mm × 1,370mm (109.0"×29.4"×53.9") |

|

|

Weight

|

140 kg (308.6 lb)

|

|

|

*1 Scheduled to be available in March 2025. - Some of the samples in this website are artificial renderings. - Specifications, design and dimensions stated in this website may be subject to change without notice (for technical improvements, etc). - The corporate names and merchandise names written on this website are the trademark or registered trademark of the respective corporations. - Inkjet printers print using extremely fine dots, so colors may very slightly vary after replacement of the printing heads. Also note that if using multiple printer units, colors could vary slightly from one unit to other unit due to slight individual differences. |

||

Related Items

Finance Calculator

- * Fixed rates for the duration of agreement

- * Major tax benefits - each payment Is 100% tax deductible

- * The equipment can be earning your next payment from day one

- * No need to have bank loans, overdrafts or pay cash

- * Fast application turnaround

- * Spread the cost of your equipment purchase

- * Protect existing lines of credit and preserve cash flow for business growth

The Tax Benefits of Leasing explained

Leasing converts a large capital expenditure into small monthly payments. Hence the company has the profit-making equipment immediately and keeps their cash reserve available.

Rather than investing the precious cash reserves in depreciating assets, the company can use them to help increase profits.

Lease Rental is 100% Tax deductible

The main reason that the majority of companies lease rather than purchase equipment is that they use leasing as a method of reducing their tax bills. This is because lease rental is 100% tax deductible, and all payments made for the equipment are written off against the company’s tax bill. For any profit making business, this means a substantial saving in the real cost of acquiring equipment by lease rental. This could mean a saving of between 20-40% of the lease payments, depending on the rate of tax you pay.

Payments on qualifying leases are written off as direct operating expenses, rather than a debt or outstanding liability, thus reducing short term taxable income.

Any capital allowances are passed on to you, and lease payments can be offset against taxable profits. VAT can also be reclaimed on monthly payments. This status as a “lease” as opposed to a “liability” on a company’s balance sheet is something the banks like to see, which is why an operating lease can be attractive. For this reason, leasing is often referred to as ‘off balance sheet’ financing – a tremendous advantage to both large and small businesses.

Ownership at the end of the lease

Lease rental is just that, a rental or hire agreement. Title of the goods remains with the Lessor (either Kennet or assigned to a bank), which means the equipment does not show on the companies balance sheet, therefore not needing to be depreciated over a fixed period. If Kennet broker the funding, they are the “third party” involved within the lease agreements. In effect, Kennet buys the equipment from the supplier and then sell it on to the customer. This means that the customer can take full advantage of all the benefits of leasing but still owns it at the end. (Tax loop-hole)

The disadvantage of buying equipment outright

The disadvantage to buying equipment out-right, is that the capital invested becomes a depreciating asset. This is an asset that’s value decreases over time.

The total amount that assets have depreciated by during a reporting period is shown on the cashflow statement, and also makes up part of the expenses shown on the income statement. The amount that assets have depreciated to by the end date is shown on the balance sheet.

Downloads

Related items

Code

Description

Price

Quantity