Graphtec FC9000-160 Cutting Plotter 160cm / 64 inch

Graphtec

- Code:

- FC9000-160

|

Availability: |

|

| Please call to check availability as the cutter are not always in stock and we can't guarantee availability! |

Description

Description

Graphtec FC9000-160 Vinyl Cutting Plotter

An FC Series Cutting Plotter provides a higher level of productivity and greater ease of use than any other cutting plotter on the market today.

Unlike other cutting plotters on the market, the FC Series comes as standard with media catch nets, networking capabilities, built-in cross-cutter, matching stand and is also customisable to further augment what is an already class leading product.

With 4 different widths available the FC is perfect for both small scale high volume users through to high demand wide format print shops who are looking for a highly functional print finishing solution to match up to their Solvent or UV printers.

With it’s unmatched cutting speed, powerful head pressure and included professional grade software the FC Series raises the bar to a totally new and incomparable level of performance, usability and functionality.

Class Leading Performance | Increased High Level Productivity | Premium Design & Build Quality

| Key Features |

Main Applications |

|

FC9000-1600 included Software: |

FC9000-1600 includes: |

|

Graphtec Pro Studio (For Windows) |

Matching Stand Including Lockable Castor Wheels |

|

Graphtec Studio (For MAC) |

Rear Mounted Media Stocker |

|

Cutting Master 4 (For Adobe Illustrator & CorelDRAW Integration) |

Media Catch Baskets (Front & Rear) |

|

|

Power Cable (3 Pin UK Plug) |

|

|

DVD-ROM & User Manual |

|

|

Cutting Blade Holder (PHP33-CB09N-HS) |

|

|

Cutting Blade (CB09UB) |

|

|

Loupe – For Checking Blade Length & Condition (PM-CT-001) |

|

|

Fibre-Tipped Pen Holder (PHP31-FIBER) |

|

|

Water-Based Fibre Tipped Pen (KF700-BK) |

FC9000 in Depth

Best in Class Capabilities

The FC9000 Series offers best in class productivity and abilities with a wider range of compatible media.

Wide Cutting Area For Full Media Use

All FC9000 models have a minimum cutting width of 50mm, the maximum cut width is determined by the width of machine you opt for.

Auto-Paneling

To prevent skew of long-length cutting, the auto-paneling function automatically splits long-length jobs into smaller pages that are then cut sequentially. It shortens feed length of the media and enables a more stable cut through the machine. This is the ideal solution when cutting a job that is potentially longer than the guaranteed long-length tracking capabilities of the machine.

User-Friendly Built-In Control Panel

Save 2 user settings with 8 condition settings for each user. A fast access key allows quick switching between users. One cutter can be shared by multiple users or for multiple purposes.

Improved & Increased Long-Length Tracking

The FC9000 supports long-length tracking of up to 15m as standard. For the wider 140 or 160cm wide models there is a now an automatic take up roller option which can be added to the plotter prior to purchase. Adding the take up roller increases media tracking accuracy up to 20m.

Data Output Via USB Flash Memory Without PC

When cutting data designed with Graphtec Pro Studio and sent with cutting Cutting Master 4 are saved to USB flash memory, they can be output directly to the cutting plotter by plugging in the USB drive directly into the plotter which means the machine can be used without the need for a computer.

Print & Cut Features

A.R.M.S 8.0 Optical Eye

The FC9000 is equipped with the latest A.R.M.S (Advanced Registration Mark Sensing) 8.0 System to allow for easy and highly accurate print & and cut applications for pre-printed media. This system allows you to cut out around pre-printed designs to create adhesive-back labels and stickers or die-cut / perforation cut through card to create packaging samples out of card.

New Data Link Function (Barcode Data Management For Continuous Cutting)

By reading the Graphtec original barcode the FC9000 automatically detects its linked data from the PC or USB flash memory. This function is available regardless of which printer or RIP software is used.

Continuous Cutting

Barcode data management allows for cutting different data sequentially by detecting the “Start Mark” of the new type of barcode. Sequential P&C process with roll-media is now available.

Supports Coloured Marks & Speciality Media

The FC9000 supports a wide range of media types including holographic paper and reflective sheets. This has been made possible to the machines improved ARMS 8.0 Sensor algorithm.

Supports Adobe Illustrator “Crop Marks”

Using Cutting Master 4 plug-in software, Adobe Illustrator crop marks will be available.

Segment Area Compensation (XY

This function has been implemented in addition to the current X-axis Direction Segment Area Compensation. Middle mark is now available not only for X but also Y-axis alignment.

Expanded Cutting Area

It expands the cutting area to include objects outside of the area enclosed by registration marks. Production efficiency is enhanced by reducing media waste.

Machine Options

| FC9000-75 | FC9000-100 |

| • Width: 75cm • Supplied Push Rollers: 2 • Guaranteed Area Of Cut Accuracy: 742mm x 15m • Max Mountable Media Width: 920mm • Max Cross Cut Width: 762mm • External Dimensions: 1360 x 1151 x 1232 (49kg) |

• Width: 100cm • Supplied Push Rollers: 3 • Guaranteed Area Of Cut Accuracy: 1047mm x 10m • Max Mountable Media Width: 1224mm • Max Cross Cut Width: 1067mm • External Dimensions: 1665mm x 1151mm x 1232mm (56kg) |

| FC9000-140 | FC9000-160 |

| • Width: 140cm • Supplied Push Rollers: 4 • Guaranteed Area Of Cut Accuracy: 1352mm x 10m • Max Mountable Media Width: 1529mm • Max Cross Cut Width: 1372mm • External Dimensions: 1970mm x 1151mm x 1232mm |

• Width: 160cm • Supplied Push Rollers: 4 • Guaranteed Area Of Cut Accuracy: 1607mm x 10m • Max Mountable Media Width: 1850mm • Max Cross Cut Width: 1626mm • External Dimensions: 2224mm x 1151mm x 1232mm |

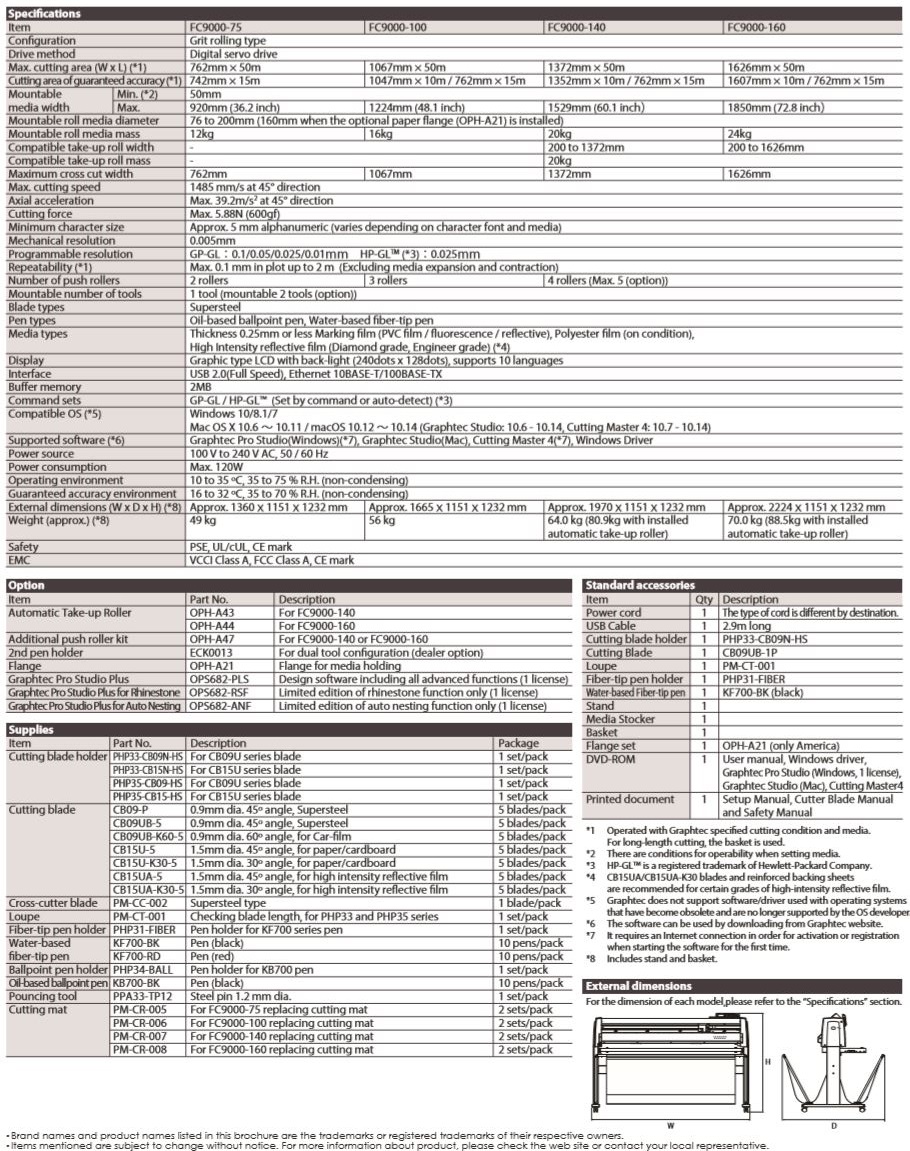

Specification

|

Machine Specification |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15m Standard | 20m Enhanced With Take Up Spool Installed On 140 & 160 Versions |

|

|

|

|

|

GP-GL: 0.1 / 0.05 / 0.025 / 0.01 mm HP-GL™: 0.025 mm |

|

|

Max. 0.1 mm In Plot up to 2m |

|

|

Yes (Performed By Force Control) |

|

|

YES |

|

|

YES |

|

|

|

|

|

Related Items

Graphtec FC9000-100 Vinyl Cutting Plotter

Finance Calculator

- * Fixed rates for the duration of agreement

- * Major tax benefits - each payment Is 100% tax deductible

- * The equipment can be earning your next payment from day one

- * No need to have bank loans, overdrafts or pay cash

- * Fast application turnaround

- * Spread the cost of your equipment purchase

- * Protect existing lines of credit and preserve cash flow for business growth

The Tax Benefits of Leasing explained

Leasing converts a large capital expenditure into small monthly payments. Hence the company has the profit-making equipment immediately and keeps their cash reserve available.

Rather than investing the precious cash reserves in depreciating assets, the company can use them to help increase profits.

Lease Rental is 100% Tax deductible

The main reason that the majority of companies lease rather than purchase equipment is that they use leasing as a method of reducing their tax bills. This is because lease rental is 100% tax deductible, and all payments made for the equipment are written off against the company’s tax bill. For any profit making business, this means a substantial saving in the real cost of acquiring equipment by lease rental. This could mean a saving of between 20-40% of the lease payments, depending on the rate of tax you pay.

Payments on qualifying leases are written off as direct operating expenses, rather than a debt or outstanding liability, thus reducing short term taxable income.

Any capital allowances are passed on to you, and lease payments can be offset against taxable profits. VAT can also be reclaimed on monthly payments. This status as a “lease” as opposed to a “liability” on a company’s balance sheet is something the banks like to see, which is why an operating lease can be attractive. For this reason, leasing is often referred to as ‘off balance sheet’ financing – a tremendous advantage to both large and small businesses.

Ownership at the end of the lease

Lease rental is just that, a rental or hire agreement. Title of the goods remains with the Lessor (either Kennet or assigned to a bank), which means the equipment does not show on the companies balance sheet, therefore not needing to be depreciated over a fixed period. If Kennet broker the funding, they are the “third party” involved within the lease agreements. In effect, Kennet buys the equipment from the supplier and then sell it on to the customer. This means that the customer can take full advantage of all the benefits of leasing but still owns it at the end. (Tax loop-hole)

The disadvantage of buying equipment outright

The disadvantage to buying equipment out-right, is that the capital invested becomes a depreciating asset. This is an asset that’s value decreases over time.

The total amount that assets have depreciated by during a reporting period is shown on the cashflow statement, and also makes up part of the expenses shown on the income statement. The amount that assets have depreciated to by the end date is shown on the balance sheet.

Video Tutorial

FC9000 - Basic Operation

FC9000 - Print & Cut

FC9000 - Advanced Features

Related items

Code

Description

Price

Quantity