S Class 3 D160 D-Series Cutter - 1600mm

Summa

- Code:

- S3D160

|

Availability: |

|

| Please call 01442 26 26 26 to check stock as we can't guarantee availability! |

Description

Description

Summa S3 D160 62" / 1600mm Drag Knife Vinyl Cutter & Plotter

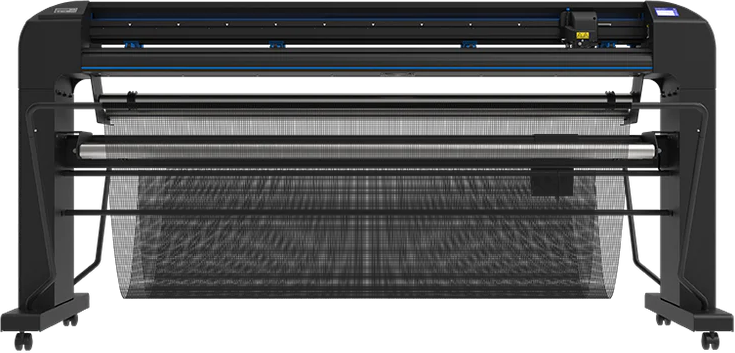

The S Class 3 Series offers the largest roll cutter size for professional users seeking maximum flexibility and advanced technology. With leading-edge cutting performance and excellence, this machine is tailored to meet the most demanding applications and requirements.

The S3 D160 (drag knife) offers maximum versatility and productivity, making it perfect for professionals. Its ability to handle media up to 158cm (+7cm in oversized mode) makes it ideal for large-format projects, providing the capability to tackle a wide range of creative endeavours.

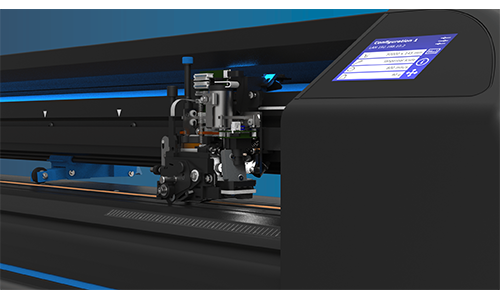

The Summa S3 D160 is equipped with advanced cutting technology and either a drag or tangential knife, allowing for more control and pressure, ensuring precision and efficiency in every cut. Unlock the power of full automation with the Summa S3 D160.

Experience the next level of cutting power with the Twin X functionality, which combines the Summa S3 160 with the F1612 flatbed cutter. This powerful combination is designed to enhance your workflow efficiency and take your business to new heights.

With advanced cutting technology and the option of a Drag (D) or Tangential knife (T), it provides precise control and efficient performance for every cut.

Experience the full potential of automation with the Summa S3 D160. With the simple setup of placing a printer in front of the roll cutter, you can effortlessly transition from printing to cutting without any manual intervention. Additionally, by choosing the roll-up unit, you can neatly roll up the processed material instead of letting it fall into the basket.

Drag Knife (D) Cutting Technology

When processing designs for billboards, light boxes, window graphics, and similar media, the drag or swivel technique is widely utilized in the market. However, it is important to note that depending on the thickness of the media, there may be some distortions or deviations in the corners when using this technique.

Summa drag knife cutters are designed with advanced techniques to prevent distortions and improve the drag movement for superior cutting quality. These enhancements ensure that the cuts are precise and accurate, providing the best possible results for any application.

True Tangential (T) Cutting Technology

The highly engineered tangential cutting heads on the S Class 3T digital cutter series have a unique motorized knife, allowing the cutters to achieve unparalleled accuracy and precision down to the smallest details. The True Tangential cutting technology even handles heavy sandblasts, paint masks, and reflective materials.

Enhanced Cutting Precision

By leveraging the Smart Object Sorting feature, efficiency is enhanced as it is designed to consistently choose the best starting point for cutting. Furthermore, the Smart Panelling function enhances cutting precision and streamlines post-processing tasks. For instance, when the panelling is configured, all objects within the specified size range are cut simultaneously.

|

GoSign cutting software tailored to your needsThe Summa GoSign software included with the machine is a powerful tool that allows you to manage your preferred workflow straightforwardly and with great flexibility. With GoSign, you can easily streamline your processes and work with efficiency.

|

OPOS Alignment for smart production (S Class 3 TC)The new camera is more performant with even faster recognition abilities thanks to automatic data processing in the cutter instead of the external software. It allows you to excel with extremely fast and precise cutting of short or long-run contour-cutting jobs.

|

Ergonomic TouchScreenThe intuitive menu system and ergonomic touch interface allow for effortless navigation. Tactile and easy to use, the touchscreen displays large amounts of information in an easily accessible format.

|

||

|

Smart Object Sorting and PanellingThe Smart Object Sorting feature is a game-changer when it comes to efficiency. By automatically selecting the best starting point for cutting objects, it ensures that no time is wasted. And with the Smart Panelling function, cutting accuracy is improved and post-processing is made easier. For instance, setting the panelling allows all objects within that size range to be cut simultaneously, streamlining the cutting process.

|

Dual Head FunctionalityThe Dual Head functionality of the cutter allows for the simultaneous use of a knife and fibre pen or a knife and creasing tool, maximizing productivity and efficiency.

|

Ethernet, USB and WiFi connectivityMultiple computers can control one unit across a network via Ethernet, USB or WiFi. Also, a crossover cable can be used for direct connection - creating an all-new avenue for faster communication and data transmission speeds. WiFi: Region dependent |

||

|

Enhanced ease-of-useDiscover improved ease of use with a blue, green, and red-lighted status bar. Additionally, swiftly identify adjustable components by their blue colour. This is complemented by a strategically placed tool tray at the back for efficient operation. The S Class 3 is also designed with a focus on ergonomics and simplicity in usage. |

TC Series OPOS CameraThe Optical Positioning System is an automated contour alignment system. The OPOS X sensor technology senses 4 to 128 marks on a wide range of materials. Now, the camera on the S Class 3 Series is more performant with even faster recognition abilities. . |

S Class 3 has three different headsThe S Class 3 has three different heads available: the D series, specifically for drag knife technology, the T series, for tangential knife technology, and the TC Series, which combines the knife and fibre pen or knife and creasing tool.

|

S3 160 Series FeaturesThe cutters in this series are known for:

|

S3 Class ToolsDifferent tools can be inserted in the cutting head to achieve different cutting effects and accommodate various materials. Cutting, creasing, and drawing on your materials has never been this easy. Get the most out of your S Class 3 with the following tools: Ballpoint pen, Fibre pen, Tangential knife, Drag knife & Creasing tool.

|

AN EVER-GROWING RANGE OF APPLICATIONSThe Summa S3 D160 62 inch / 160 cm cutter can cut an infinite number of applications to meet the needs of different signage and graphic production. |

S Class 3 TC Series Specifics & Features

With the S Class 3 TC models, users can expect an even more advanced camera system for superior performance. The automatic data processing within the cutter ensures faster registration of marks, eliminating the need for external software. Coupled with our powerful True Tangential Cutting Technology and knife pressure of up to 1000 gr, these models are engineered to deliver unparalleled cutting excellence.

- Unique True Tangential cutting technology

- Higher accuracy by placing 'in-field' registration marks

- Accurate fixed-size cutting with Fixed-size mode

- Job segmentation to preserve the best tracking performance

- Mark registration about 10 times faster than any other light sensor

- Custom camera profile to process challenging media types

- Features Dual Head technology: knife + fibre pen or knife + creasing

These features are available as Summa S Class 3 TC cutters TC75 & TC160 cutter models.

Specification

| MODELS | S3 D75 | S3 D120 | S3 D140 |

S3 D160 |

| CUTTING TYPE | True Tangential knife (T) with Drag knife (D) cutting mode capability | |||

| CUTTING WIDTH | 74.2 cm x 50 m 'Oversized' mode allows a wider cutting area: +/7 cm |

120 cm x 50 m 'Oversized' mode allows a wider cutting area: +/7 cm |

135 cm x 50 m 'Oversized' mode allows a wider cutting area: +/7 cm |

158 cm x 50 m 'Oversized' mode allows a wider cutting area: +/7 cm |

| MEDIA WIDTH | 6 to 84 cm | 11.4 to 130 cm | 17 to 145 cm | 17 to 168 cm |

| CUTTING SPEED | All S3 models cut at speeds up to 56 inches (1440 mm) per second diagonal | |||

| AXIAL ACCELERATION |

Up to 4.2 G diagonal | |||

| ALIGNMENT TYPE |

|

|||

| TRACKING PERFORMANCE |

12 m max. within guaranteed specifications for media less than 760 mm 4 m max. within guaranteed specifications for media larger than 760 mm |

|||

| MEDIA THICKNESS | 0.05 mm to 0.25 mm / Up to 0.8 mm with sandblast drag knife / Up to 1.2 mm with sandblast tangential knife | |||

| ACCURACY | 0.2% of move or 0.25 mm, whichever is greater | |||

| SPEED | Up to 1440 mm/s diagonal | |||

| KNIFE PRESSURE | Drag Knife (D): Up to 400 grams / Tangential Knife (T): Up to 1000 grams | |||

| EXTRA PEN OR CREASER PRESSURE | Up to 1000 grams | |||

| OTHER FEATURES | FlexCut (cutting through) | |||

| CONNECTIVITY |

Ethernet, USB, WIFI* (*region dependent) |

|||

| POWER REQUIREMENTS | 100-120 / 220-240 VAC, 50/60 Hz,85 VA maximum | |||

| DIMENSIONS | 55.5 (W) x 27.2 (D) x 43.7 (H) in. 141 (W) x 69 (D) x 111 (H) cm | 73.6 (W) x 27.2 (D) x 43.7 (H) in. 187 (W) x 69 (D) x 111 (H) cm | 79.6 (W) x 27.2 (D) x 43.7 (H) in. 202.2 (W) x 69 (D) x 111 (H) cm | 88.6 (W) x 27.2 (D) x 43.7 (H) in. 225 (W) x 69 (D) x 111 (H) cm |

| SHIPPING WEIGHT | 69 kg (152 lbs) | 86Kg (189 lbs) | 90Kg (198 lbs) | 114Kg (251 lbs) |

| OPERATING TEMPERATURE |

59˚ to 95˚F (15˚ to 35˚C) | |||

| INCLUDED SOFTWARE | Summa GoSign Software, Summa Cutter Control / Plug-in: Illustrator, CorelDraw, MacSign | |||

| CUTTING TECHNOLOGY | Drag knife (D) or Tangential knife (T) | |||

| DUAL HEAD FUNCTIONALITY | S Class 3 tools - the cutter can carry a knife and fibre pen or a knife and creasing tool | |||

| STANDARD ACCESSORIES | WinPlot or MacSign Cut Software, CutterControl Parameter Software, CD w/ Manuals and Drivers, Quick Start Guide, Power Cable, USB Cable, Media Guide Flanges (set of 2), 1 Spare Fuse, Blade Holder, Standard Nose Piece, 2 Standard 36° Tangential Blades, Thick Material Nose Piece, 1 Thick 60° Blade, Tangential Drag Holder, 1 Standard 36° Drag Blade, Pouncing Pin and Holder, T Pen holder, 1 Ball point pen, Pouncing and Pen Nose Piece, 2 Cut-off Razor Blades, Blade insertion tool, Stand and Basket. | |||

Note: In 'Oversized' mode, the tracking performance is no longer guaranteed.

Related Items

Finance Calculator

- * Fixed rates for the duration of the agreement

- * Major tax benefits - each payment Is 100% tax-deductible

- * The equipment can be earning your next payment from day one

- * No need to have bank loans, overdrafts or pay cash

- * Fast application turnaround

- * Spread the cost of your equipment purchase

- * Protect existing lines of credit and preserve cash flow for business growth

The Tax Benefits of Leasing explained

Leasing converts a large capital expenditure into small monthly payments. Hence the company has the profit-making equipment immediately and keeps their cash reserve available.

Rather than investing the precious cash reserves in depreciating assets, the company can use them to help increase profits.

Lease Rental is 100% Tax deductible

The main reason that the majority of companies lease rather than purchase equipment is that they use leasing as a method of reducing their tax bills. This is because lease rental is 100% tax-deductible, and all payments made for the equipment are written off against the company’s tax bill. For any profit making business, this means a substantial saving in the real cost of acquiring equipment by lease rental. This could mean a saving of between 20-40% of the lease payments, depending on the rate of tax you pay.

Payments on qualifying leases are written off as direct operating expenses, rather than a debt or outstanding liability, thus reducing short term taxable income.

Any capital allowances are passed on to you, and lease payments can be offset against taxable profits. VAT can also be reclaimed on monthly payments. This status as a “lease” as opposed to a “liability” on a company’s balance sheet is something the banks like to see, which is why an operating lease can be attractive. For this reason, leasing is often referred to as ‘off balance sheet’ financing – a tremendous advantage to both large and small businesses.

Ownership at the end of the lease

Lease rental is just that, a rental or hire agreement. Title of the goods remains with the Lessor (either Kennet or assigned to a bank), which means the equipment does not show on the companies balance sheet, therefore not needing to be depreciated over a fixed period. If Kennet broker the funding, they are the “third party” involved within the lease agreements. In effect, Kennet buys the equipment from the supplier and then sells it on to the customer. This means that the customer can take full advantage of all the benefits of leasing, but still owns it at the end. (Tax loop-hole)

The disadvantage of buying equipment outright

The disadvantage to buying equipment out-right, is that the capital invested becomes a depreciating asset. This is an asset that’s value decreases over time.

The total amount that assets have depreciated by during a reporting period is shown on the cashflow statement, and also makes up part of the expenses shown on the income statement. The amount that assets have depreciated to by the end date is shown on the balance sheet.

Related items

Code

Description

Price

Quantity